- Order tracking

- Wishlist

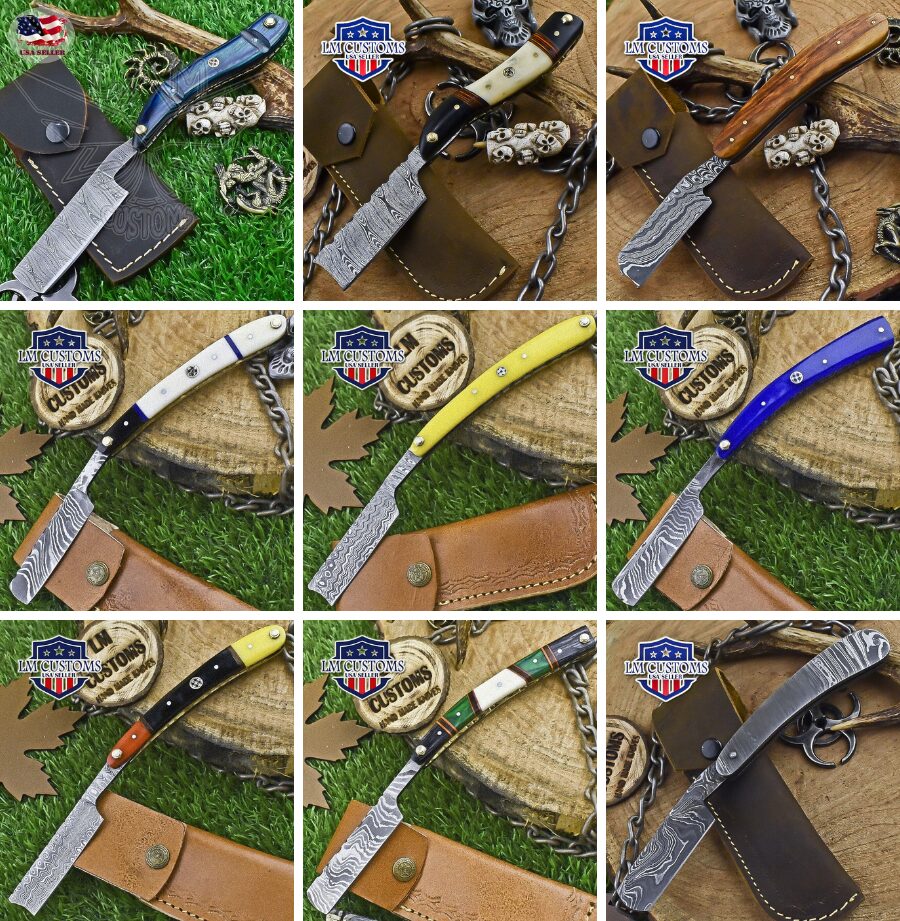

Razor knives sold in bulk are vital in many fields, such as building and arts to regular home use. Though they might look simple, the materials and forms of these knives greatly affect how they work, how long they last, and how people find using them.This article tells the critical aspects of razor knife materials and designs, providing insights for those looking to purchase these tools in bulk knives

Razor knives mostly have blades made of steel. But remember, not all steels are alike. Did you know there are two popular steel types of razor knives? Yes, they are stainless steel and carbon steel. Indeed, each has its special features and advantages.

Stainless Steel: Stainless steel blades are renowned for their resistance to rust and corrosion. Using these is perfect when there’s a chance the blade might touch water or rust-inducing particulars. Plus, the edge of stainless steel remains razor-like for a long haul and demands less upkeep. That’s why they’re a favorite in the bulk selling sector.

Carbon Steel: Carbon steel blades, Contrarily, they’re valued for keen edges and lasting sharpness. They’re typically tougher than stainless steel, so they have a finer cutting edge. But, they might rust more easily, needing extra upkeep. Still, their excellent slicing ability usually makes them a top pick for pros

A razor knife’s grip is as critical as its sharp edge. The substance used for the grip influences the knife’s lifespan, feel, and general look.

Plastic: Plastic handles are lightweight, cost-effective, and can be molded into various shapes and textures to enhance grip. They are also moisture-resistant, making them a practical choice for many applications.

Wood: Wooden handles offer a classic look and a comfortable grip.They hold up well, even with lots of use. Still, they need more upkeep than plastic ones and might not work best everywhere.

Composite Materials: Mixed handles, crafted from things such as Croain or Micarta, Used in Custom Razor knives and mix the winning features of plastic and wood. Their robustness is admirable, they repel moisture like a champ, and they offer top-notch grip This makes them the go-to option for premium razor knives.

The knife’s blade design is vital for its effectiveness. There are many shapes and thicknesses for razor knife blades, each perfect for unique tasks.

Blade Shapes: The most common blade shapes include straight edge and serrated. Straight-edge blades are ideal for precise, clean cuts, while serrated blades excel at cutting through tougher materials like rope or fabric.

Blade Thickness: The thickness of the blade also plays a significant role in its performance. Thinner blades offer more precision and are better for detailed work, while thicker blades provide more strength and are better suited for heavy-duty tasks.

The handle design of a razor knife can greatly impact its usability. Ergonomic considerations are essential to ensure that the knife is comfortable to hold and use for extended periods.

Ergonomics: Ergonomic handles are designed to fit comfortably in the hand, reducing fatigue and the risk of injury. They often feature contours and textures that enhance grip and control.

Grip Textures and Patterns: The texture and pattern of the handle can also affect the knife’s usability. Textured handles provide a better grip, especially in wet or slippery conditions. Patterns such as checkering or ridges can enhance the overall feel and control of the knife.

Safety tops the list when designing razor knives. Different features are make sure the knife is safe to use. First, you have Blade Locking Mechanisms. These are key for folding knives. They make sure the blade remains tight while you’re using it, stopping unexpected shut-offs that could harm. Second, Protective Sheaths or Covers come into play. For foldable and fixed-blade knives, these is crucial. They guard the blade while idle, warding off accidental slices during stowing or moving the knife.

Quality and reliability are crucial when it comes to razor knives. A high-quality knife will perform better and last longer, reducing the need for frequent replacements.Wholesale knives work the best

Wrapping up, the make and model of bulk razor knives are important for their function and longevity. Getting to know the varied choices and thinking about touchpoints like planned use and finances, brings you closer to selecting a fitting razor knife. Staying up to date with new materials and models, as industry trends change, assists you in making optimal buying choices. Regardless of your work in building, arts and crafts, or another field that counts on these key instruments, picking the appropriate razor knife has a significant impact.

Answer: The most common materials used for razor knife blades are stainless steel and carbon steel. Stainless steel is known for its resistance to rust and corrosion, while carbon steel is prized for its sharpness and edge retention.

Answer: Stainless steel blades offer excellent resistance to rust and corrosion, require less maintenance, and retain their sharpness over time. These properties make them ideal for environments where the knife might be exposed to moisture or corrosive elements.

Answer: Carbon steel blades are harder than stainless steel blades, allowing for a sharper edge. They are preferred by professionals for tasks requiring precision cutting. However, they require more maintenance to prevent rust.

Justin

Typically replies within minutes

Feel Free to ask any question related to Wholesale query.

WhatsApp Us

🟢 Online

WhatsApp us